Are block homes better than wood frame homes in Florida?

The Fairy Tale… Once Upon a Time

When I was a young boy, one of my favorite stories was the one about the big bad wolf and the three little pigs in which “Big Bad Wolf” tries to destroy the pigs’ homes so he could have a nice meal. The wolf easily blew down the house made of straw and had no problems mowing over the home made from sticks. When the wolf attempted to destroy the house made from bricks, he was unsuccessful and could not blow it down even with all of his huffing and puffing. The pigs in the brick home lived happily ever after.

Now for the Reality…

Selecting the ideal material for your dream home goes beyond the tales of straw houses and wary wolves. While the fabled house of sticks succumbed easily in stories of yore, modern building science and engineered wood framing techniques have transformed wood into a sturdy and reliable choice for construction. Yet, the tale’s brick house, once deemed the epitome of durability, reveals a different truth in the real world.

Bricks, serving merely as a decorative facade, provide no structural support and bear no weight beyond their own. This highlights the importance of choosing materials that not only appeal to the eye but also meet the rigorous demands of Florida’s unique climate and building requirements.

Most of Florida’s residential exteriors are built using one of two structural methods. One method is engineered frame wood construction and the other method is concrete block construction or CMU construction (short for concrete masonry unit).

Engineered Wood Frame Construction

The exterior walls are constructed with 2 x 4 or 2 x 6 dimensional lumber. The lumber member is spaced between 12″ and 16″ on center and is determined by the engineer using required building codes. The wall is anchored from the bottom of the wall at the slab to the top of the wall. The wall sits on a pressure treated 2×4 on top of a weather barrier that sits on the concrete slab itself.

The exterior walls are constructed with 2 x 4 or 2 x 6 dimensional lumber. The lumber member is spaced between 12″ and 16″ on center and is determined by the engineer using required building codes. The wall is anchored from the bottom of the wall at the slab to the top of the wall. The wall sits on a pressure treated 2×4 on top of a weather barrier that sits on the concrete slab itself.

Structural engineers design a new home for wind loads, sheer value, up lift and hold down protection. Rods, cables, clips and other hardware are incorporated into the design. The use of fasteners and nail spacing and patterns are also part of the design.

On both wood frame and CMU construction, the same wood roof trusses/rafters, sheeting and interior lumber walls are used. In the case of CMU homes, the second floor is usually built in wood frame for cost savings.

The exterior of the wall has OSB or plywood as sheeting with a certain nailing pattern applied to penetrate the wood studs for maximum strength and rigidity.

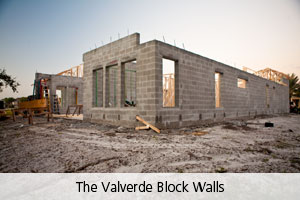

Concrete Block Construction (CMU)

CMUs are cement blocks made from a mold in a factory. Typically a residential exterior wall made from CMUs measures 8″ x 8″ x 16″ and is 80 % hollow.

The CMUs are laid on top of the slab in an interlocking staggered method and the wall is raised to its desired height. Mortar holds each block in place.

Once the CMU wall is constructed, some of the hollow block cells are filled with concrete in the cells that hold vertical rebar. The top of the wall consists of a “poured in place” concrete lintel that ties everything together.

People wonder why Florida has a combination of both wood frame and concrete block homes. The northern part of the state as well as the panhandle and some central Florida areas are mainly built in wood frame. The other areas in the state generally build CMU homes even though the majority of homes with a second floor are constructed out of engineered wood frame construction.

In my view, both methods under discussion comply fully with current building standards, which mandate that structures be capable of withstanding winds up to 120 mph. This compliance suggests that either choice could be considered acceptable. However, the preference for Concrete Masonry Units (CMU) by some individuals is based on the perception of increased safety during a hurricane. It’s important to acknowledge that while the exterior walls of a CMU-built home are indeed more robust compared to those of a wood-frame construction, this does not guarantee the home’s overall integrity post-hurricane. Even if a CMU structure’s walls remain intact, significant damage to essential components such as the roof, windows, and doors could still result in the home being considered a total loss. Consequently, the most prudent course of action for residents facing the threat of a Category 4 hurricane, with winds surpassing 131 mph, is to evacuate the area. This allows the complexities of property damage and insurance claims to be addressed by professionals in the aftermath, ensuring personal safety remains the priority.

Pros and Cons about Block (CMU) vs Wood Frame

Concrete Block (CMU)

- Better sound proofing

- Durability during a hurricane

- A “simple box” one-story home could be less expensive than wood frame. (Not always the case with more intense design, angles and varying wall heights.)

- Some say CMU has a better fire rating however the roof and interior walls are still wood frame.

- Better protection from termites. This is true but most builders on all homes now provide termite colony elimination systems that ward off termites and provide very sizable insurance bonds if termites strike.

- Not as energy efficient as a wood framed home

- Possible dampness in areas of the walls that can be trapped within

- Higher cost on larger, high-end homes due to more complicated design elements

- The block size dimension is wider than a 2 x 4 or 2 x 6 thus robbing a couple of inches from a room located on an exterior wall area.

- Harder to rout mechanical rough-ins such as electrical and plumbing or retro-fitting wiring

Engineered Wood Frame

- Meets building code wind requirements just like CMU homes

- Much more energy efficient due to having deep wall cavities for various types of insulation

- Allows greater freedom in design for multiple wall heights, angles, curves and other detail at an affordable level

- Improved moisture protection due to advancements in house wrapping products in the last several years

As a long experienced Florida builder, I am comfortable with both methods of construction, but prefer wood frame mainly due to the ability to maximize energy efficiency. Insurance cost is similar these days in both methods. Like most trade industry associations, the masonry association may be at odds with the wood frame industry and each will have opinions that one is better that the other. When you build your Florida home, you should feel at ease with either of the two methods described here because your builder will have a reason as to why they specialize in one or the other….or both.

So, who’s afraid of the Big Bad Wolf? You shouldn’t be now that you know!

Want to talk to an ICI Homes representative? Reach out to us here.